Explain Difference Between Oil and Oiless Air Compressors

The Teflon coatings will eventually wear off at which point most people throw the air compressor away and purchase a new one. Oil-less operation combined with extensive drying and filtering processes virtually eliminates the possibility of air contamination.

An oil-free compressor doesnt use any oil in the compression process while an oil-lubricated compressor uses a small amount of oil to help cool and lubricate the compressors internals.

. Oil-less compressors work by first expelling air filtering the air to eliminate contamination pressurizing air and finally cooling air for use. Therefore its a great choice for industrial compressors. Thats where we come in.

At really low temperature oil increases in. 10 rows Pros and Cons of Oil-Free Air Compressor Pros of Oil-Free. More oil equals better lubrication which results in quieter operation versus oilless air compressors.

The difference is the oil content in compressed air. Oil-less air compressors are much lighter but not very powerful. An oil air compressor uses special oil to lubricate moving internal parts and reduces friction.

Simple Single-Stage Oil-Flooded Rotary Screw Flow Diagram. If the ambient temperature is consistently low oil-free air compressors operate optimally. Oil-free compressors are typically smaller and less expensive than their oil-lubricated counterparts but they also have shorter lifespans and are less efficient.

Ad Large Variety Free Shipping On Select Air Compressors. Ad Shop Oilless Air Compressor With Tank Talk to an Air Compressor Expert Today. The main advantage of oil-less compressors is that they do not require periodic replacement of oil.

Unlike oil-free compressed air systems oil-flooded compressors require specialized equipment such as oil separators and filtration systems to minimize the threat of oil carryover from impacting other critical system components downstream. So the main difference between an oiled compressor and an oil-less compressor is that oil-less compressor pistons have their own built-in lubrication while oiled air compressor pistols rely on an external liquid lubricant. Splash lubrication is the most common method used in these air compressors and uses dippers to pull oil from a reservoir and splashes it upwards to coat the moving parts of the compressor and prevents damage.

Many of these compressors use. It is widely believed that air compressors that do not use any oil are not very durable or sturdy which does not make them as valuable. Typically these compressors fail at about 2 000 hours of use.

An oil free compressor is not completely free of oil rather there is no oil in the compression chamber and the components that require oil for lubrication such as bearings and gears are isolated from the compression chamber itself keeping the resultant compressed air 100 free of oil contaminants. Oil air compressors utilize oil and may not need as much periodic maintenance as other types of compressors but they may be more expensive in the long term. Despite being larger and more heavy-duty oriented than their counterparts oil-lubricated air compressors tend to be quieter than oilless ones.

The opposite can be said for extremely cold climates. Another big difference is in maintenance. Another benefit of the oil-based lubrication is wearing and tearing are less likely to take place.

What Is an Oil Air Compressor. This means that in a hot climate oil lubrication would be more beneficial. On the other hand it is believed that oil air compressors are more durable robust and last a long time because they require regular maintenance and use oil.

Are oil free air. Sliding piston is carried through the use of materials with a low coefficient of the friction. Oil air compressors are likely to be more durable and more functional.

Operating environment can also be a deciding factor. Air compressors come in two primary varieties. How Much Will It Be Used.

And it can be very tough to decide between the two of them. Whereas an oil-lubricated compressor would usually use oil for cooling. As its lubricated by oil the amount of noise created is also less than oil-less air compressors.

The main difference between oilless and oil air compressor units is this oil and the need to make sure that it is there. They usually last longer. Oil air compressors and oil-less air compressors.

Oil-less Compressed Air Reference NFPA99 Edition 2012 Exhibit 514. The additional oil that coats the moving parts of the air compressor provides extra durability and tends to lead to longer lifespans thanks to reduced internal wear-and-tear. It also means that the operator will need to change it occasionally which means more maintenance.

Pros and Cons of an Oil Air. Oil-less compressors are often used for similar applications to what oil-free compressors are used for. For the Class 0 oil-free air compressor we use water as the lubricating medium instead of oil Water-injected oil-free single-screw air compressor or use no lubricating medium Dry oil-free double twin-screw air compressor so there will be no oil at all.

It is also thought that they have a shorter lifespan. Oil contaminates the air Oil-Free Compressors These types of pumps duplex operate at lower RPM reducing the noise heat and friction which extends the pumps life cycle and mixed with better castingsexacting tolerances and better frictionless coatings make oil-free a great choice in many applications. Weve put together an in-depth comparison of oil and oil-less air compressors to help you understand how each one works and what their different pros and cons are.

Refers to an air compressor that has no oil in the air compressor units whatsoever. They have always had a reputation for being very noisy and loud during working. Not in the compression area and not in the drive area.

Oil-less compressors still greatly decrease the risk of contamination which is why they are often confused with oil-free compressors. Ad Find Deals on oilless air compressor in Tools on Amazon. The oil-less compressor is designed with a shorter life expectancy than lubricated compressors.

Only by ensuring that the proper amount of oil gets into the cylinder and piston will the pump operate the way it should. Oil air compressors require special compressor oil which must be replaced periodically. Oiled air compressors are designed for heavy-duty and long-term use and they need regular maintenance in order to keep the operation running smoothly and efficiently.

Oil-free air compressors rely heavily on air cooling.

Which One To Choose Oil Vs Oilless Air Compressor Comparison Guide Air Compressor Compressor Air Compressor Oil

Peerless Oil Less Air Compressor Po13 00590 Air Compressor Compressor Electric Motor

Silent 6 Gallon Oil Free Air Compressor Silent Air Compressor Air Compressor Compressor

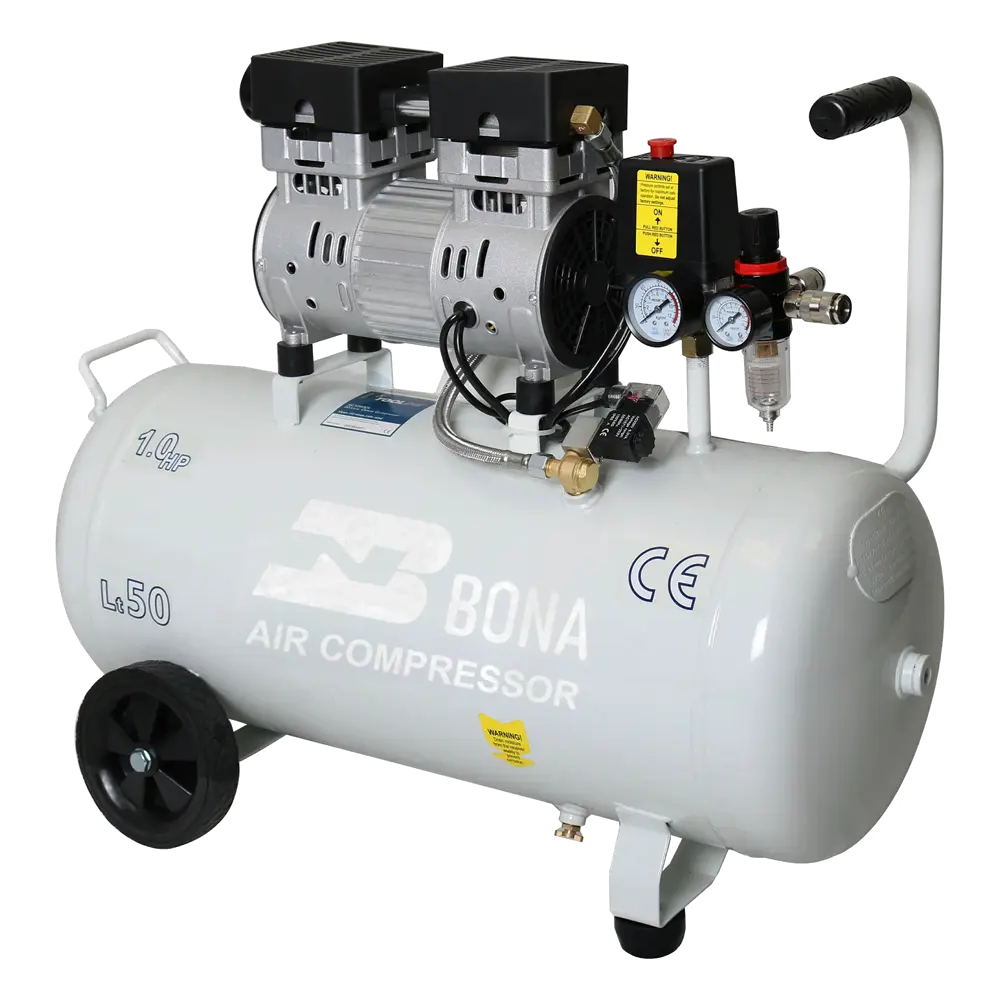

China 550w 750w 50l Oil Free And Silent Air Compressor China Oilless Air Compressor Piston Air Compressor

Oil Free Air Compressor Oilless Air Compressor Oil Less Air Compressor त ल म क त एयर क प र सर ऑयल फ र एयर क प र सर In Raipur Punjab Machinery Mart Id 20696115130

Silent Oil Free Air Compressor L 6 105 8 Bar 0 6 Hp 25 L Min 6 L

California Air Tools 1hp 8 Gallon Oil Free Aluminum Tank Air Compressor In 2022 Air Tools Air Compressor Compressor

Compressor Set Assembly Part Tca35111301 Best Portable Air Compressor Electric Air Compressor Portable Air Compressor

Oil Vs Oilless Air Compressor 5 Differences That Matter

Quipall 2 1 Sil Al 1 Hp 2 Gallon Oil Free Hotdog Air Compressor Oil Free Air Compressor Gallon

Size Air Compressor Need For Air Tools Silver Air Tools Portable Air Compressor Air Compressor

Oil Vs Oilless Air Compressor Which Is For Home Or Industrial Use

Oil Vs Oil Less Air Compressor Which One Is Best

Craftsman Air Compressor 6 Gallon Pancake Oil Free With 13 Piece Accessory Kit Best Portable Air Compressor Craftsman Air Compressor Portable Air Compressor

Beli Swan Compressor Oil Less Portable Type Kompresor Angin Monotaro Id

Rolair 1 Hp 2 5 Gal Quiet Oilless Air Compressor Best Portable Air Compressor Quiet Air Compressor Portable Air Compressor

Comments

Post a Comment